CANTILEVERS

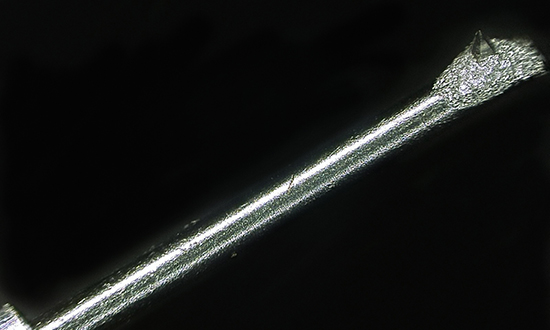

Boron

Delicate sound

Boron, one of the most suitable materials for cantilevers; its density is low, Young’s modulus is large, and the speed of sound propagation is approximately 2.6 times faster than that of aluminum. Due to the characteristics above, boron cantilever can more precisely trace the information contained in the record grooves than aluminum cantilever.

BORON CANTILEVER

SAS/B

Sapphire

Clear & deep sound

The reproducibility of the sound engraved on analog records is further enhanced by adopting sapphire for cantilevers since it has high rigidity. Compared to aluminum cantilevers, every single sound will be defined more clearly, allowing the users to enjoy crystal-clear sound. Superior impression that the vocals are extremely clear.

SAPPHIRE CANTILEVER

SAS/S

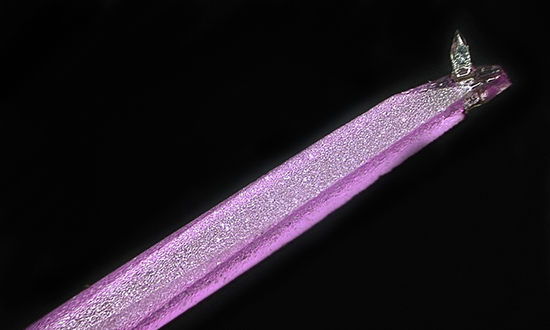

Ruby

Realistic & Sharp sound

The SAS/R enjoys all the sapphire benefits with one crucial advantage: The four facets of its crystalline ruby cantilever taper toward the diamond tip. This tapered design allows for lower moving mass, providing greater ability reproduce vibrations in the record groove with precision, accuracy, speed, and fidelity. The sound is deeper and has the impression of listening to a live performance

RUBY CANTILEVER

SAS/R

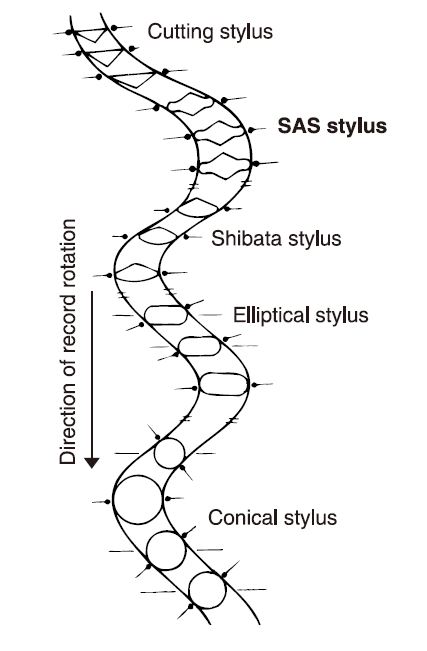

SAS Profile Tip

The tip of the Super Analog Stylus is carefully chosen from single-crystal natural diamonds. The laser-cut diamond closely resembles that of the cutting stylus used on a cutting lathe to produce the acetate master disks used in vinyl production. This allows the SAS tip to reach into the deepest recesses of the record groove in order to retrieve details which were previously inaccessible to other stylus profiles. Due to its wide contact area with the groove wall, the SAS can reproduce a more expansive bandwidth of information with higher fidelity.

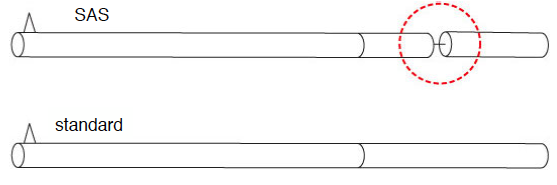

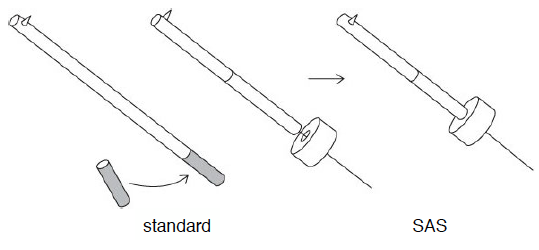

Single Point Tension Wire Suspension

In order to transmit vibrations from the stylus tip to the transducer magnet faithfully, the cantilever is supported by a specially constructed suspension. A single strand of ultra-fine piano wire is attached to the cantilever which then passes through the magnet before being secured internally to the housing. This helps to stabilize the movement of the magnet and reduce distortion from resonance that builds up as oscillations are transmitted through the cantilever, thus preserving the original signal down to the smallest detail.

Rare Earth Magnet

To extract the maximum performance from the single point tension wire a specially shaped magnet is mounted coaxially to the cantilever. The magnet is composed of rare earth elements, the magnetic strength and reduced weight of which give it exceptional properties for use in this application.

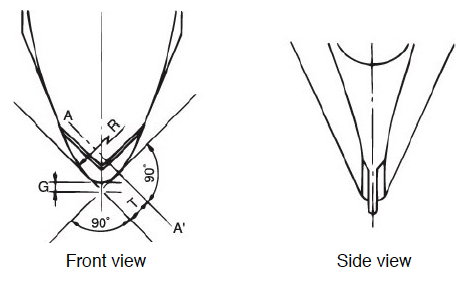

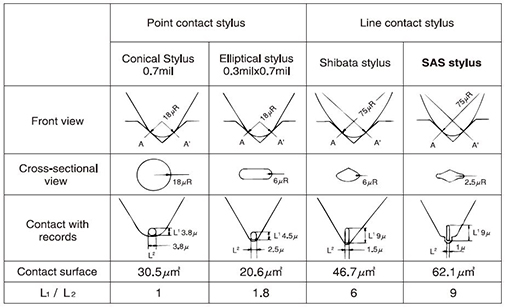

Contact Surface Area & Stylus Tip

This chart depicts several types of stylus profiles viewed head on and in cross section. Also seen are the measurements of their tip radii and the surface area in contact with the record groove wall. Profile radii (R) are measured in microns (µ). Surface area in square microns (µ2) is calculated using measurements L1 and L2. Variations in the size and shape of the stylus tip affect the amount of surface area which can be applied to the groove wall. By optimizing its curvature and reducing the minor radius, the SAS tip maximizes the contact surface area by a factor of 1.25 in comparison to other line contact styli.

Points of Contact with the Record Groove During Reproduction

This chart depicts several types of stylus profiles viewed head on and in cross section. Also seen are the measurements of their tip radii and the surface area in contact with the record groove wall. Profile radii (R) are measured in microns (µ). Surface area in square microns (µ2) is calculated using measurements L1 and L2. Variations in the size and shape of the stylus tip affect the amount of surface area which can be applied to the groove wall. By optimizing its curvature and reducing the minor radius, the SAS tip maximizes the contact surface area by a factor of 1.25 in comparison to other line contact styli.

-Faithful Sound Reproduction

To produce the highest possible original sound recording, SAS utilizes a pure diamond tip with high precision finishing within several microns. The line contact tip profile features a contact area in the shape of narrow belt or "micro ridge". Previously it was almost impossible for tips of shape to achieve a radius of such microscopic curvature. By means of extremely detailed machining, our SAS tip provides the razor-like dimensions necessary for accurate sound reproduction and clarity.

-Elimination of Distortion through wear resistance.

By processing the diamond structure to maximize its natural property of resistance to wear, the curvature of the tip radius remains intact allowing it to accurately trace the signal in minute detail. The true value is in its radius curvature, its ability to reproduce high-frequencies even as it moves toward the inner portions of the record to ensure dynamic range.

-High Trackability

Our SAS cantilevers are rigid in comparison to conventional cantilever materials. Other components used in SAS have significant influence on the performance of the stylus. As oscillations are transmitted from the tip to the magnet to suspension wire through the cantilever and rubber suspension, the unique combination of technologies built into the system results in superlative tracking ability.

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using ‘Content here